Introduction:

Refrigerant safety classification is paramount for ensuring the safety and efficiency of cooling and air-conditioning systems. ASHRAE Standard 34 provides a standardized approach to categorizing refrigerants based on their safety characteristics, including toxicity and flammability. Understanding these classifications is crucial for manufacturers and consumers alike to ensure the safe use and disposal of refrigerants.

Refrigerant safety classification explained

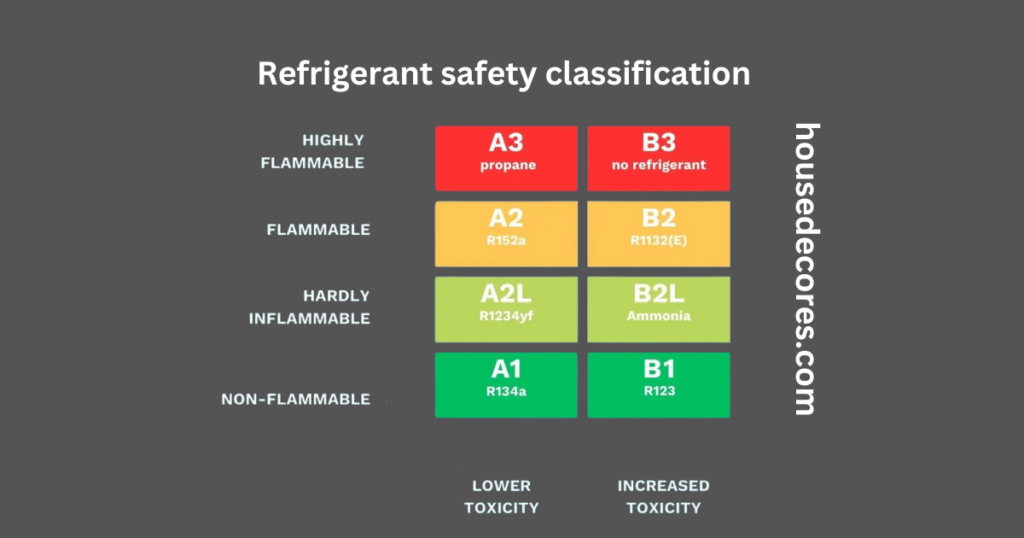

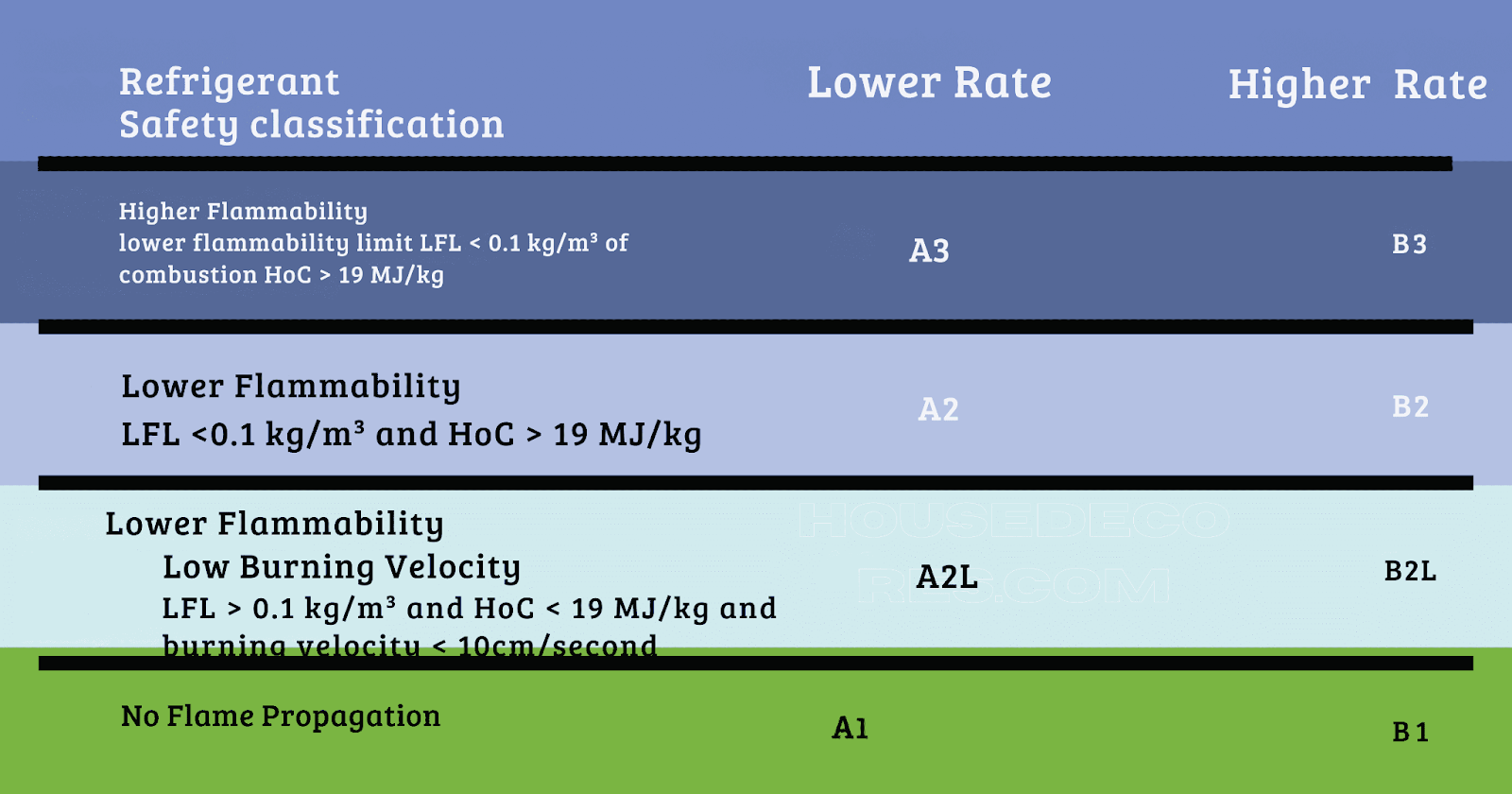

Refrigerant Safety Classification is governed by ASHRAE Standard 34, which categorizes refrigerants into classes ranging from class 1 to class 4, indicating varying levels of toxicity and flammability.

In which class 1 refrigerants are considered safe for household use due to their low toxicity and non-flammability, while class 4 refrigerants pose extreme risks due to their high toxicity and flammability. A proper understanding of these classifications is essential for safe refrigerant handling and disposal.

Toxicity and flammability classification

Determining the toxicity and flammability of refrigerants is critical for ensuring safety. Classifications range from low-toxicity and non-flammable (class 1) to highly toxic and flammable (class 4), with classes 2 and 3 falling in between.

Awareness of these classifications is vital for consumers, technicians, and manufacturers to mitigate potential hazards to human health and the environment.

R-Number designation

The R number is one of the most critical aspects of refrigerant identifiers, as it provides information about properties and compositions. R-numbers are assigned by organizations, such as the American Society of Heating, Refrigerating, and Air-Conditioning Engineers, to aid in the proper handling, service, and disposal of refrigeration.

It is used to standardize the classification of refrigerants based on molecular structures, chemical compositions, and environmental impacts.

The R-number designator allows consumers and technicians to select the best refrigerant based on their cooling needs. This ensures optimal performance, safety, and environmental protection. R-numbers also help to facilitate regulatory compliance and industry standards, improving efficiency and sustainability in refrigeration technologies.

Low GWP refrigerants

Low GWP refrigerants have a lower environmental impact than traditional alternatives. These refrigerants are less likely to emit greenhouse gases and help mitigate climate change. These include blends of R1234yf or HFOs. The adoption of low-GWP refrigerants has increased due to increasing environmental awareness and regulations. This is driving innovation in more sustainable refrigeration systems.

A2L refrigerants

A2L refrigerants offer a safer alternative to A3 and other highly flammable varieties. Fires or explosions are less likely to occur. A2L is also more environmentally friendly because it has a lower Global Warming Potential.

Although they require care to avoid accidents, A2L refrigerants offer an excellent balance between safety and eco-friendliness. A2L refrigerants, which promote safety and sustainability, are more popular as environmental regulations become stricter.

Hydrocarbon refrigerants

Hydrocarbon refrigerants like propane (R290) and isobutane present environmentally friendly alternatives to traditional refrigerants. Despite their minimal environmental impact, it’s crucial to handle them with care due to their flammability.

These refrigerants are gaining popularity for their energy efficiency, aiding in energy conservation and greenhouse gas reduction. Understanding the proper handling procedures outlined in the Mitsubishi mini split manual is essential for users to ensure safe operation.

Refrigerant handling guidelines

These protocols are essential for ensuring the safe management of refrigerants throughout their life cycle, from installation through disposal. The protocols involve the proper storage of refrigerants to prevent leaks. They also include prompt leak detection, responsible recycling practices, and disposal.

Personnel must be adequately trained to understand safety precautions and risks. These guidelines are essential to ensure safety, system longevity, environmental protection, and safe use.

Flammability limits

Flammability limits are the ranges of concentrations where refrigerant and air mixtures can ignite. It is essential to understand these limits for safe handling of refrigerants. There are specific upper and lower flammability limits for refrigerants, above which ignition becomes too rich or too lean. It is vital to stay within these limits to reduce the risk of fire or explosion.

And then, proper ventilation and leak detection are also necessary to prevent the accumulation of flammable refrigerants in enclosed spaces. Refrigeration systems can be operated safely by adhering to the flammability limit and taking safety measures.

Refrigerant Safety codes

The refrigerant safety code is a set of regulations and guidelines established by the International Code Council to make refrigeration systems safe for handling, installation, and maintenance. These codes describe best practices in designing, constructing, and operating refrigeration systems to minimize risks to the human body and environment.

These codes cover various topics, including refrigerant choice, system design, and leak detection. Here are the safety codes for refrigerants:

- Non-Flammable, Lower Toxicity Refrigerants Group A1.

- Carbon Dioxide R744.

- Flammable Lower Toxicity Refrigerants Group A2L, A2 and A3.

Refrigerant safety codes, rules, and guidelines are essential standards to ensure refrigerants’ safe handling, storage, and use. These codes outline procedures for technicians and workers to follow when working with refrigeration systems to prevent accidents and environmental harm.

They typically include guidelines for proper ventilation, leak detection, and equipment maintenance to minimize the risk of exposure to harmful gases or chemicals.

Conclusion:

It is essential to classify refrigeration systems according to their safety. This will ensure that they operate safely and efficiently. It is necessary to categorize refrigerants by their environmental impact, flammability, or toxicity. This helps technicians, manufacturers, and consumers make informed decisions.

For the industry to remain standard and minimize potential hazards, refrigerant safety code compliance must be adhered to. Understanding the classification of refrigerators will help create a safer and more sustainable future for refrigeration technology.